Products

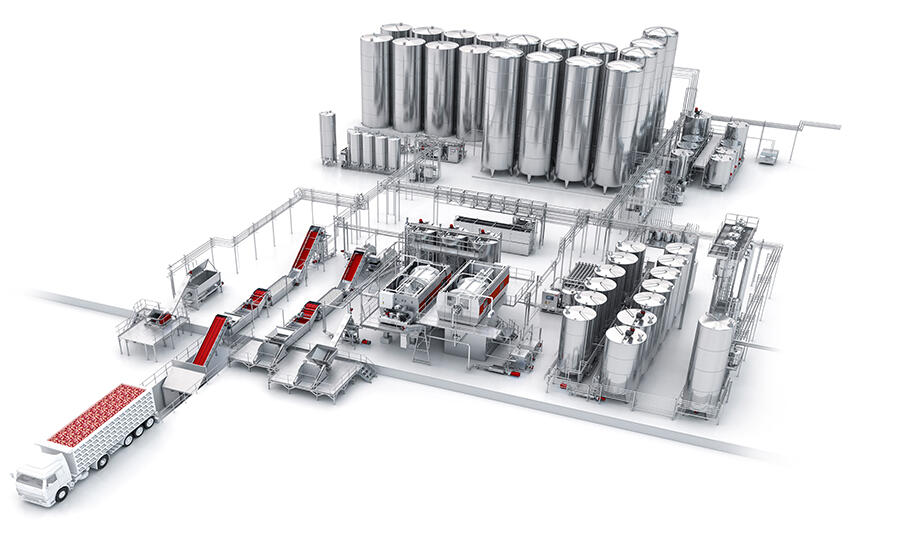

Our machines and production lines are used in countless applications, specifically for the beverage, food and environmental industries.

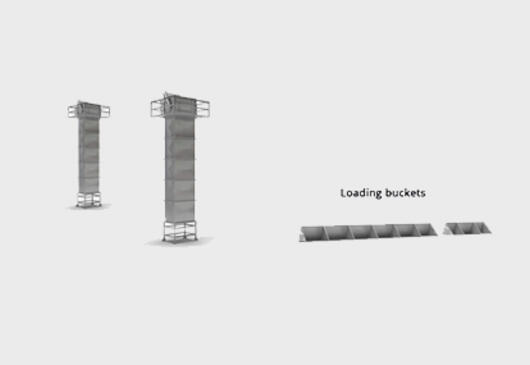

Transport and conveying

Reception Lines

- Flexible and storage capacity

- Fast unloading of the trucks

- Easy to clean / hygienic set-up

- Low maintenance cost

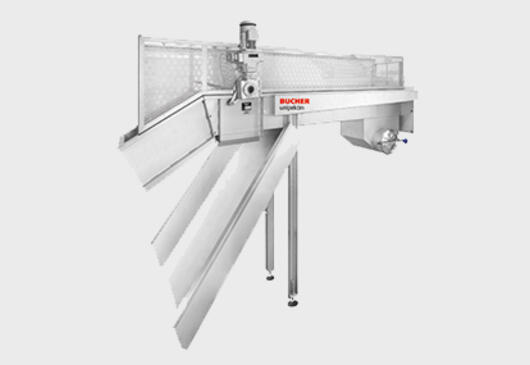

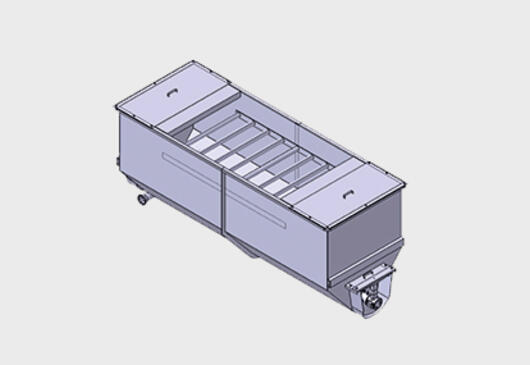

Dosing-Hasp

Dosing Hasp used for the flushing channel.

- Dosing and stopping devices for controlling the fruit flow

- Integrated water and dirt separation

- Optionally with stone trap

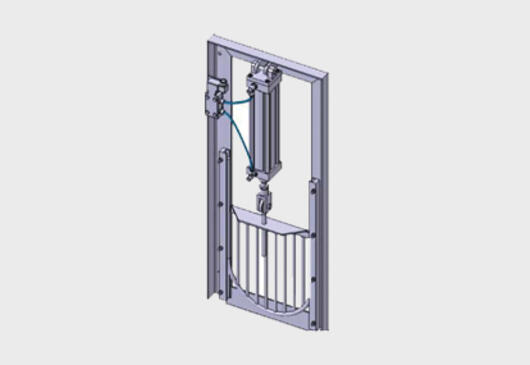

Dosing-Slide-Airmatic

Dosing Slide for water-tight closing of pome fruit silos and dosing into the flushing channel.

- Flooding of the silos enables unloading via truck

- Water-tight Airmatic seal

- Steady dosing of pome fruit into the flushing channel

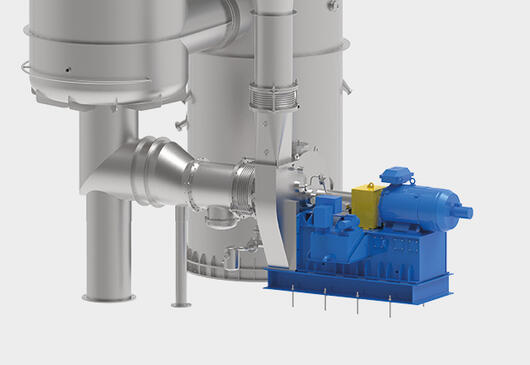

Elevator

Vertical screw elevator for transporting pome fruit.

- High throughput with a small footprint

- High reliability with low maintenance

- Efficient separation of water and dirt

- Fresh water cleaning if needed

Vertical Bucket Elevator

High lifting capacity between high slopes using a small space.

Find out more

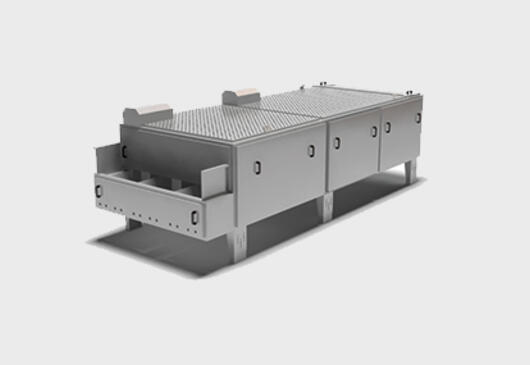

Roller Table

Roller table for sorting and cleaning of pome fruit

- Full inspection of fruit surface through rotating, gripped rollers

- Automatic dirt removal via rinseable tray underneath the belt

- Integrated cleaning nozzles

Citrus Sorting Table

Manual selection and rejection of citrus fruits of insufficient quality for processing.

Find out more

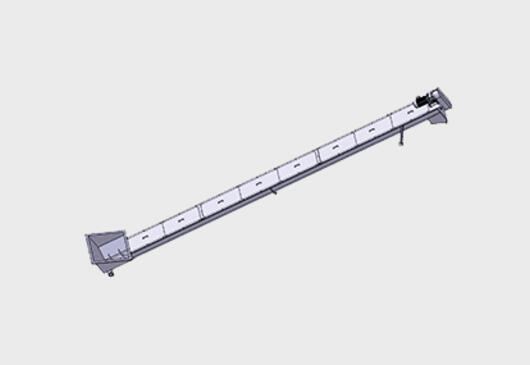

Dewatering Screw Conveyor

Dewatering screw conveyor for screenings.

- Screw conveyor with an integrated dewatering zone

- Transport and dewatering of screenings from the flushing water circuit

Transport Screw Conveyor

Transport screw conveyor for discharging and conveying of pomace.

- Variable length and inclination of the conveyor

- Robust design and execution

- Easy access

Dosing Slide

For isolate pome fruit silos and controlled dosing into the flushing channel.

- Variable opening and closing times

- Robust pneumatic drive

Citrus Brush Washer

Mechanical washing system with rotating brushes and water spray nozzles.

Find out more

Citrus Sizer

Inline calibration of citrus fruits using inclined rails with adjustable motorised rollers.

Find out moreGrinding Technology and Crusher Systems

Grinding Mill C25

Grinding mill for apples, pears, berries and vegetables.

- Bucher grinding technology for optimal mash structure

- High yield and throughput during juice extraction

- High grinding capacity with low energy consumption

- Easy cleaning and maintenance

Grinding Mill CM50

Grinding disc mill for apples, pears, berries, vegetables and herbs.

- Optimal mash structure increases yield and throughput during juice extraction

- Minimal oxidation

- Low noise emission

- Easy cleaning and maintenance

- Independently adjustable milling and feeding drives

Crushing Mill KVS 2-80

Roller mill for the crushing of berries and stone fruits

- Original and well-established Bucher concept which allows the creation of optimal mash structure

- High yield and throughput during juice extraction

- Continuously adjustable grinding gap with a more flexible degree of digestion

- Electronic overload protection

- Easy cleaning and maintenance

BMH Hammer Mill

- High durability

- Simple and very effective process

- Quick and easy maintenance

- Smooth operation mode

- Low operating costs

- Wide range of applications

- Dedicated to vegetables

Crusher Systems

Efficient emptying and processing of open top cylindrical and conical drums containing frozen fresh juice or concentrate.

- PLC control and monitoring of the entire process

- Double pneumatic system for lifting the barrels

- CIP spray cleaning system

Drum Dumper

Semi-automatic system for emptying drums of juice in liquid state and pumping the discharged product on to the next process.

Find out moreSolids liquid separation

Exzelplus citrus juice extractor

Exzelplus extractor with 6 extraction heads for 20% more processing capacity

- Plus 20% capacity

- Oil recovery in just one stroke

- Separation of the juice from fruit peels and bitter substances

- Maximum juice yield

- Adaptable components

- Optional cleaning system

- Improved electrical cabinet with additional alarms

- New food grade solid plastic feeding tray

Bucher HPX presses

Universal hydraulic filter press for the extraction of juice from apples, pears, berries, stone fruits and vegetables.

- Highest juice yield with little suspended solid content

- Completely closed and secure hygienic design

- Integrated one to three step leaching system

- High reliability and low maintenance

- Self-optimising process control with data recording

- Proven unique design

Bucher HPS presses

Hydraulic filter press for dewatering of municipal and industrial sludge.

- High degree of dewatering

- Low disposal and drying costs

- Reliable process and control system

- Self-optimising process operation

- Continuous operation without supervision

- Minimal labour costs

- Minimal maintenance costs

Screw Finisher

High quality and performance solid - liquid separation system by rotating auger and perforated mesh, dragging and pressing the product throughout its length.

Find out more

Paddle Finisher

High quality and performance solid - liquid separation system by perforated mesh and helical paddles rotating at high speed, driving the product for sieving.

Find out more

Collecting Screw Conveyor

Collecting Screw Conveyor for residue discharge from the Bucher HPX/HPS press.

- Hopper volume sufficient for residue of a press charge

- Fast discharge of the hopper

- Four sizes for 1–4 presses

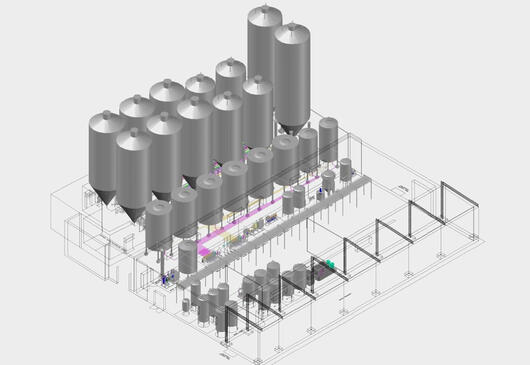

Brewing solutions

Brewhouse technology

Innovative brewhouses technology

Our proven process components and technical expertise are based on our own research and development.

- Turnkey projects

- Modernisation and optimisation

- Hop technology

- Process plants

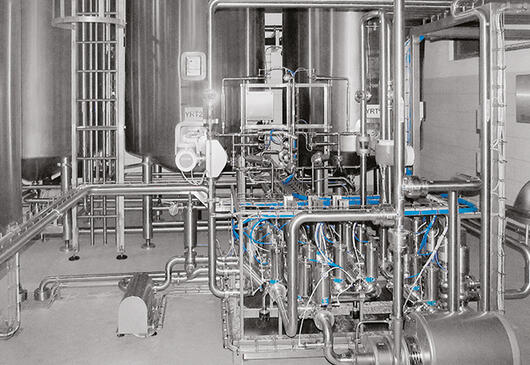

Cold block technology

The complete equipment for the Cold Block.

- Yeast plant and beer recovery

- Fermentation and maturation cellar

- Filtration and bright beer cellar

- Water deaeration and blending

- CIP

Inline Aeration/Oxygenation Manual unit

- Micro bubble size

- Instant saturation

- Sterile gas and steam filters

Inline Aeration/Oxygenation Automatic unit

Designed for fast and accurate injection and dissolution of air or oxygen for continuous wort aeration.

- Micro bubble size

- Instant saturation

- O2 analyser controlled

Yeast Plant

Propagation, storage and pitching.

- Various yeast strains

- Flexible design

- Highest hygienic standard

Cerinox BR

For beer recovery from surplus yeast.

- Short payback period

- Economic system with diafiltration

- High quality of recovered beer

Reconnection Lantern

Automatic unit

- Safe beverage transfer

- Automatic air removal

- Minimises extract losses

- Instant reconnection from empty to selected tank

- Controlled beer flow to minimize oxygen pickup

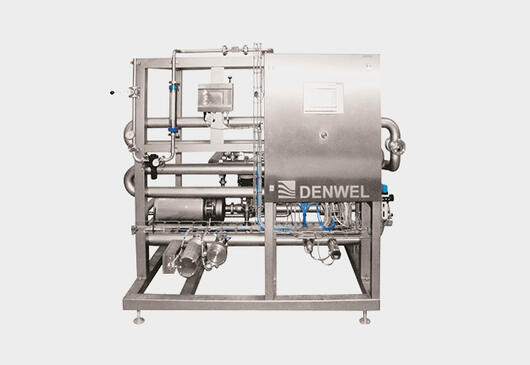

M-Polynox MC

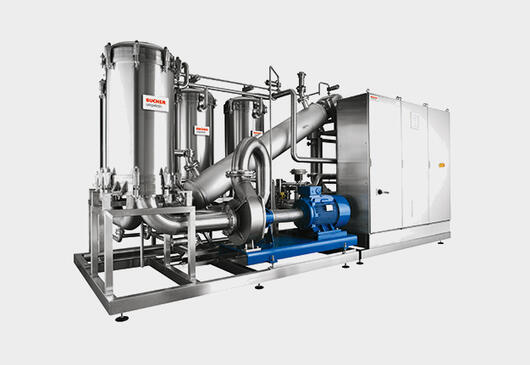

D.E. free crossflow beer filtration with polymer membranes.

- Bright, yeast-free filtered beer

- High flexibility for a wide range of beer types

- Easy to operate

Polynox MF

Kieselguhr free beer filtration with innovative filter cartridges with organic membranes

- Bright, yeast free filtered beer

- High flexibility for a wide range of beer types

- Longer average lifetime of membranes due to cartridge concept

- Easy expandability

Kieselguhr/Stabiliser

Compact unit

Kieselguhr/PVPP preparation and deaeration vessel.

- Final Oxygen below 30 ppb

- CO2 / N2 and energy savings

- Safe and hygienic design

- Turnkey unit or upgrade

M-Synox BF

The small filter for beer and beverage filtration.

- Compact design

- Plug and play

- Best value for money

Synox 2.0 PF

Precoat candle filter

New generation of candle filter offering the most efficient and economical solution.

- Reduced pre- and post-run

- Reduced beer losses

- Reduced cleaning water consumption

Synox 2.0 PS

Candle filter for PVPP stabilisation and treatment of beer and other beverages.

- Reliable beer stabilisation

- Low PVPP losses

- Easy to handle

Securox BF

For particle and final filtration of beer after precoat filters.

- Two chamber design

- Safe particle retention

- Efficient back wash

Dosing Unit

Continuous dosing of one or more additives into beverage, water or cleaning solution.

- Full capacity range

- Vessels with stirrer

- Precise and reliable dosing

Inline Carboblender

Automatic unit

Designed for fast and accurate dosage of deaerated water.

- Instand blending and CO2 saturation

- Multiple valve control for precise blending

- Alcohol, extract and CO2 analyser controlled

Water Deaeration

Column Cold Unit

Our Water Deaeration column cold unit.

- Final oxygen below 10 ppb

- Carbonation of deaerated water

- No vacuum required

- Low CO2 / N2 consumption

Water Deaeration

Column Hot Unit

Stripping technology for deaerated water production with water sterilization

- Final oxygen below 5 ppb instead of 10 ppb

- No vessels, no vacuum

- Heat Recovery up to 96%

- Compact short column

Water Deaeration

Membrane Unit

Membrane technology for deaerated water production

- Final oxygen below 10 ppb

- Water prefiltration

- Expandable capacity

Water Deaeration

Vacuum Unit

Vacuum enhanced stripping technology for deaerated water production

- Final oxygen below 10 ppb

- Very low CO2 or N2 consumption

- Efficient and hygienic design

Inline Carbonation

Mobile manual unit

- Micro bubble size

- Instant saturation

- No CO2 and flavour loss

- Efficient, hygienic design

Inline Carbonation

Semi-Automatic unit

- Micro bubble size

- Instant saturation

- Precise CO2 injection

- CO2 ratio controlled

Inline Carbonation

Automatic unit

- Micro bubble size

- Instant saturation

- Precise CO2 injection

- CO2 analyzer controlled

Carbonation/ Nitrogenation

High concentration unit

- All types of beverages

- Precise CO2 / N2 dosing

- Integrated CIP

- Integrated cooling

- Direct connection to the filler

Inline Nitrogenation

Manual unit

- Improves foam stability

- Micro bubble size

- Instant saturation

- Efficient, hygienic design

Inline Nitrogenation

Automatic unit

- Efficient, hygienic injector

- Micro bubble size

- Instant N2 dissolution

- PLC controlled

Inline Nitrogenation

High concentration unit

- Creamy head and avalanche effect

- Long-lasting foam stability

- Efficient and precise nitrogen control

- Optional decarbonation

De-Alconox B

Thermal dealcoholisation of beer.

- Processing at lowest temperatures: < 39°C

- Dealcoholisation down to <0.03% vol.

- Suitable for filtered and non-filtered beer

De-Alconox M

- Preserves aroma and taste of beer, no oxygen pickup

- Processing at low operating temperature <10 °C

- Low energy consumption

- Compact design with minimum space requirement

Hard Seltzer

Continuous unit

Customized continuous technology for production of mixed drinks

– Continuous and precise production of mixed drinks

– “Just in Time” production without the need for storage and conditioning vessels

– Immediate switch over to another product with minimal losses

– Numerous individual recipes

Flash Pasteurizer

Automatic unit

Heat treatment with the purpose of improving the microbiological stability of beverages to prolong shelf life.

- Gentle and precise heat treatment

- Consistent pasteurization

- Heat recovery up to 96%

Stefinox

Skids for cold sterile filtration of beer.

- Standardised skids for easy installation

- Prefiltration, sterile filtration and media filtration all on one skid

- Maximum safety and cartridge lifetime

Cerinox BF

The reliable solution for D. E. free beer filtration with ceramic membranes.

- Absolutely yeast free beer

- Sterilisation 85°C possible

- Long life time of membranes

- No frequent membrane change

- No expensive cleaning agents

Sud Sixty Six

- 6 brews/day with only two vessels

- small footprint

- down to 3.5 kWh/hl thermal energy consumption

- 109°C/228°F heating media - also alternative energy generators possible

- highest flexibility in grist load

- fully automated

- vessels without heating surfaces

- decoction possible

- low in maintenance

Flavorit Cone

- targeted extraction of the lupulin glands

- increases in bitterness can be controlled

- complete, effective extraction in just 20 minutes – “dry nests” do not form in the hops

- a completely automated process, including CIP cleaning and spent hop discharge

- flexibility: can be used for whole hops, herbs and flower petals

- up to 200 kg of whole hops

- reduces the load on the whirlpool

- installation between the whirlpool and wort chiller or for use with the wort kettle

Exergon Brew®

energy optimization

- < 4 kWh/hl thermal energy requirement in the brewhouse

- simple retrofittability

- quick payback

- applicable for any energy source (solar, CHP, steam boiler, etc.)

- applicable for all brew sizes and brew sequences

- active resource conservation

- sustainability

- potential analysis on site

CIP mobile unit

- Three sizes of caustic and acid vessels

- For tanks, pipes and equipment cleaning

- Automatic temperature control

- Optimal cleaning performance

CIP compact unit

- Caustic, acid and water recovery vessel

- For tanks, pipes and equipment cleaning

- Automatic CIP sequencing

- Intuitive and simple user interface

- Optimal and consistent cleaning performance

CIP plant

- Fully automatic CIP programs ensure perfect cleaning

- Economical production due to full automation

- Individual programming of each cleaning circuit

- 3, 4 or 5 vessel system

- Vessel size up to 20 m3

- Up to 6 different cleaning circuits

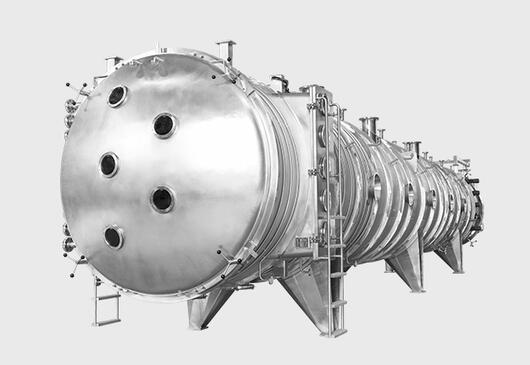

Tanks and Vessels

- CCTs, BBTs, Buffer tanks and Storage vessels

- Heating/Cooling system and Insulation

- Pressurized/Atmospheric/Vacuum

- Customized design, Vertical or Horizontal layout

- Up to volume 2 500 hl produced in workshop, larger assembled on site

Filtration

UltraStar XL

Crossflow ultrafiltration unit for the clarification of fruit juices, fruit wines, aqueous plant extracts, and fermentation broths.

- Maximum product yield and excellent juice quality

- Tubular membranes allow high solid concentrations

- Modular design, high performance on small footprint

- Reliable and fully automated system

- Integrated CIP system and tank management

Mona

Aseptic Filtration System

- Effective elimination of ACB bacteria

- Improvement of turbidity and microbiological quality of the concentrate

- Product safety during the process

- Monitoring and archiving of parameters

- Optimum use of filter plates

Cerinox MF

For wine, cider, fruit juice, vinegar and other food products.

- Standardised units

- Skid-mounted

- Ready to use

Synox 2.0 PF

New generation of candle filter for the most efficient and economical solution.

- Reduced pre- and post-run

- Reduced beer losses

- Reduced cleaning water consumption

FOM 110

For precoat filtration in various applications.

- Horizontal filter element

- Centrifugal discharge

- For syrup, beverages and food products

Microstar

Upgrade from a polysulfon filter to a modern ceramic filter.

- Easy, fast and economic

- Robust ceramic element

- Long service life

Adsorption and Ion-Exchange systems

Adsorber

Adsorption systems for clear and cloudy fruit juices

- Ideal for haze-stabilisation, decolourisation and debittering to meet customer’s product specifications

- Enhanced product quality without the use of additives

- Minimal processing cost

- Fully automatic, PLC control and PC based operation systems

Ion-Exchanger

Ion exchange systems for treatment of fruit juices and syrups.

- Production of acid-reduced or deionised fruit juices and fruit sugar syrups according to specification

- Minimal processing cost

- Fully automatic, PLC control and PC based operator interface

Thermal process

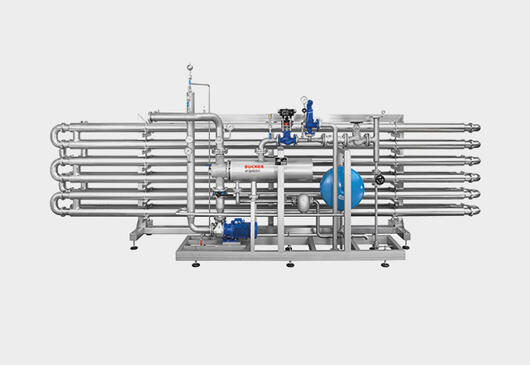

Evaporators

Tubular falling film evaporator system for the production of concentrated fruit juices and aroma essences.

- Single-pass design for maximal product yields

- Highly energy-efficient combinations of multi-stage and MVR system

- Integrated, independently controlled pasteurizer

- Sophisticated liquid distribution provides for long cleaning intervals

- Optimized CIP with high performance spray nozzles

- Also available as pure multi-stage and TVR options as appropriate

Conversion of evaporators to MVR

- Significant OPEX reduction

- 80 % reduction in fossil fuel consumption and CO2 emissions

- No modifications to the software, or only minor changes

- Reliable partner with many years of experience in evaporator conversions

Evaporators Dairy

Evaporator systems for various applications in the dairy industry.

- Multiple effect concentrators

- Milk evaporators with MVR or TVR

- Little temperature stress of the products

- Long batch-time with milk products

- Design upon request

Mash-Heater

For heating mash to receive better extraction of juice and colour for core fruits and berries.

- Pipe-in-pipe tubular design

- Gentle heating

- Compact and modular design

- Automated control system

- Easy to clean

Pasteurizer

- Wide range of pasteurisation temperature control

- CIP cleaning

- Cooling unit with buffer tank for coolant preparation

- Adjustment of holding time at pasteurisation temperature

- Cleaning system optimally adapted to the type of plates used

- Production safety - use of booster pumps

- Extended regeneration section (heat recovery)

Flash Pasteurizer

for brewers

For the safe, precise and reliable heating of beverages

Find out moreVacuum and freeze drying

QCF

- Batch process with contact and radiant heating

- Fast tray transfer and batch changeover

- Customised and high performance equipment

- Suitable for pieces, granular products or powders

- No oxidation and minimal flavour losses

- Higher throughput compared to traditional processes

- Automated operation with process profile

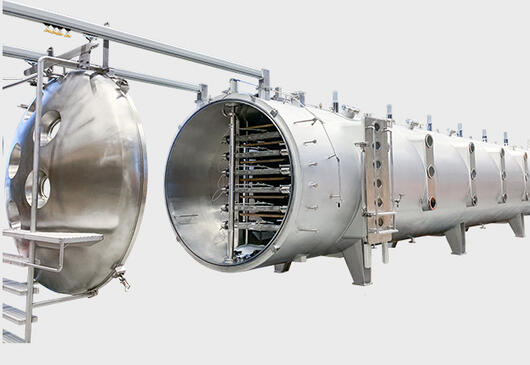

DryBand

Belt dryer for continuous vacuum or freeze drying or lyophilisation of food products.

- Continuous and gentle product drying

- Minimal oxidation

- Low energy consumption

- Minimal flavour losses

- Product specific feeding and discharging systems

- Fully automated operation & cleaning

DryBand Lyo

Belt dryer for continuous freeze-drying (lyophilisation) of coffee as well as pre-dried or frozen pieces of fruits, vegetables or meat.

Find out moreDryCab

Drying cabinet for efficient and flexible vacuum or freeze drying (lyophilisation) of heat sensitive products with frequent product changes.

- For liquid products or powders

- No oxidation and contamination

- Gentle drying of products

- Automated operation with process profile

Zeolite Reactors

Zeolite reactors for the gentle vacuum drying or freeze drying (lyophilisation) of products by mean of water adsorption.

- Maximum quality of dried products

- Best aroma retention

- Flexibility of production

- Selective process

- Batch or continuous process

DryBand mini

Top-innovation for the development and evaluation of vacuum drying processes.

- Efficient and flexible

- Easy to use

- Continuous drying operation

- Short installation and cleaning time

- Rapid optimisation of drying processes

- Visible drying process by the use of glass housing

Liquid blending and processing

Juice Mixing Station

- High degree of protection against operating errors

- Easy to operate

- Possibility to enter a wide database of recipes

- Avoid contamination of the product with the cleaning solution

- Guarantee of repeatability of the quality of the finished product

- Significant time savings due to optimization of production processes

- Big savings due to accurate dosing

- Process control through data archiving.

Claryfing Agent Dosing Station

- High effectiveness and efficiency

- Easy to maintain

- Fully automatic control with visualisation

- Precise dosing

- Little space required

Storage and processing

Industrial tanks

Industrial tanks tailored to customers specific and individual need

Find out moreCleaning technology

CIP Units

CIP (Cleaning in Place) is a process to reliably and safely clean production lines.

- Cost-saving operations

- Re-use cleaning solutions

- Reduce pollution

- Ideal cleaning result through pre-defined target value

CIP Compact for Brewery

- Caustic, acid and water recovery vessel

- For tanks, pipes and equipment cleaning

- Automatic CIP sequencing

- Intuitive and simple user interface

- Optimal and consistent cleaning performance

CIP Mobile for Brewery

- Three sizes of caustic and acid vessels

- For tanks, pipes and equipment cleaning

- Automatic temperature control

- Optimal cleaning performance

CIP Plant for Brewery

- Fully automatic CIP programs ensure perfect cleaning

- Economical production due to full automation

- Individual programming of each cleaning circuit

- 3, 4 or 5 vessel system

- Vessel size up to 20 m3

- Up to 6 different cleaning circuits

CIP Station

Single or Double Circuit

- High effectiveness and efficiency

- Ease of maintenance

- Fully automatic SPS control with visualization

- Small space required

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain