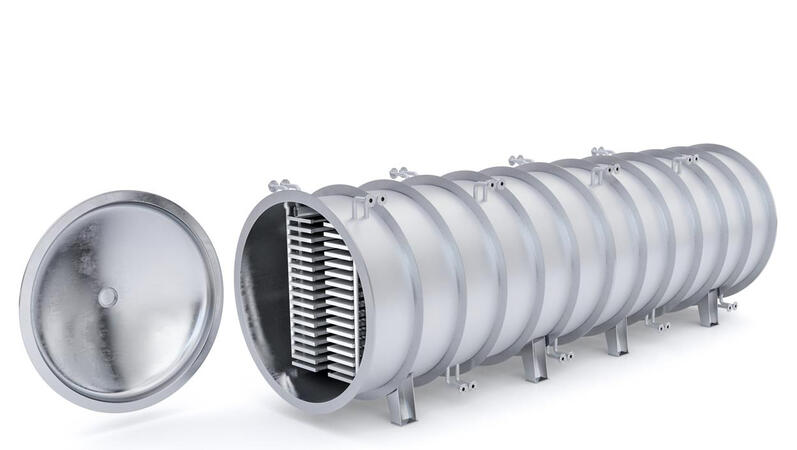

QCF – Quasi-Continuous Freeze Dryer

Efficient batch freeze drying (lyophilisation) through rapid product handling and optimised drying process

- Batch process with contact and radiant heating

- Fast tray transfer and batch changeover

- Customised and high performance equipment

- Suitable for pieces, granular products or powders

- No oxidation and minimal flavour losses

- Higher throughput compared to traditional processes

- Automated operation with process profile

The Quasi-Continuous Freeze Dryer (QCF) is designed for the efficient production of freeze-dried products in the food and pharmaceutical industries. Uniformly filled product trays are rapidly loaded into the dryer by trolleys suspended from a top-rail system. The QCF drying process is specifically designed to dry each product as gently and efficiently as possible to achieve maximum product quality in a cost effective manner. Our combination of contact (bottom) and radiant heating (top) allows higher throughputs per square metre than traditional freeze drying. End product quality is maintained by constantly measuring and limiting the critical product temperature and properly controlling the drying profile, resulting in shorter drying times. QCF vacuum and heating/cooling systems are specifically designed to utilise preferred energy sources and provide the optimum balance between short batch times and energy savings.

Optional features such as weighing of product during drying, camera for continuous drying observation, emergency cooling, automatic trolley loading/unloading, cleaning concept and turnkey concepts in combination with upstream and downstream processes are available on request.

- Coffee/Tea

- Fruits and vegetables in pieces

- Meat or sea food in pieces

- Pharmaceuticals

- Probiotics and enzymes

- Infant nutrition

- Vacuum: 0.5 - 5 mbar abs.

- Temperature max.: 150°C

- Capacity: 200 - 3.000 kg/batch

- Heating-cooling plate surface: 16 - 256 m²

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain