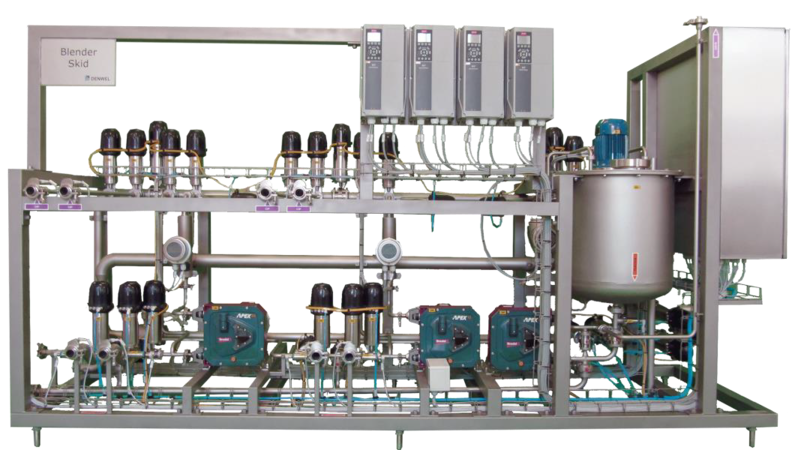

Dosing Unit

Compact Dosing Unit providing continuous dosing of additives into beverages, water or cleaning solutions.

Full capacity range

Vessels with stirrer

Precise and reliable dosing

Colour concentrate

Fruit syrup

Fructose

Bitterness

Iso hops

Tetra hops

Kieselguhr

Hydragel

Silica gel

The Compact Dosing Unit provides continuous dosing of one, or more additives, into beverages, water or cleaning solutions. A precise dosing rate is controlled by process analytics or volume / mass flow measurement. Additives can be dosed directly from barrels, storage vessels or agitated reactors and can be kept under protective atmosphere.

Medium: Beer

Pressure: 1 to 5 barg, 15 to 72 psig

Temperature: 0 to 10 °C, 32 to 50 °F CIP

Pressure: 3 to 6 bar, 43 to 87 psig

CIP Temp.: max. 90 °C, 200 °F

Models:

DDS075C DN 40 1½” 30 to 75 hl/h 14 to 33 gpm 26 to 63 bbls/h

DDS100C DN 50 2” 40 to 100 hl/h 18 to 44 gpm 35 to 85 bbls/h

DDS200C DN 65 2½” 80 to 200 hl/h 36 to 88 gpm 69 to 170 bbls/h

DDS300C DN 80 3” 120 to 300 hl/h 53 to 132 gpm 103 to 225 bbls/h

DDS500C DN 100 4” 200 to 500 hl/h 88 to 220 gpm 171 to 426 bbls/h

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain