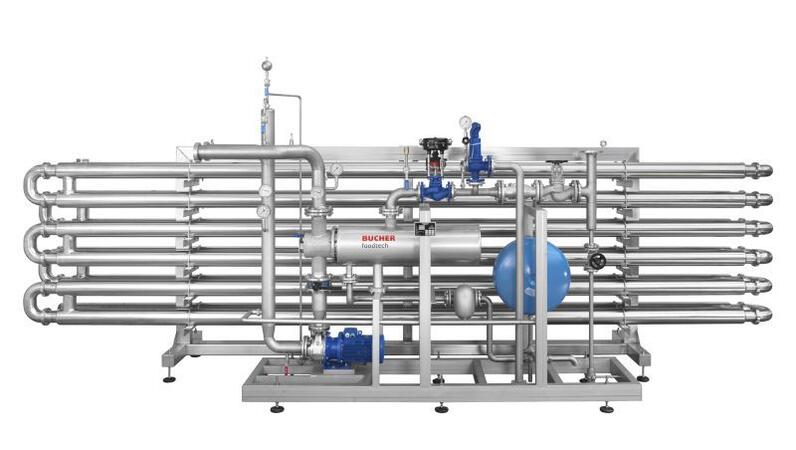

Mash heater

Enabling heating mash to receive better extraction of juice and colour for core fruits and berries.

- Pipe-in-pipe tubular design

- Gentle heating

- Compact and modular design

- Automated control system

- Easy to clean

Bucher Mash Heaters are designed to preheat various fruit mash such as apples, pears, berries and stone fruits. As a result, the enzyme activity will be increased, and the juice and colour yield will be improved.

The Mash Heater is installed between the milling and mash holding section. Users benefit from short processing time, low heat impact and easy capacity adjustments of all kinds of fruit mash.

Mash Heater systems are typically multi-section systems. The hot water station is adjustable to run different hot water temperatures. The system consists of major components such as the heating element (double tube heat exchanger module) and hot water station (tubular heat exchanger, hot water recirculation pump, expansion tank and various preassembled pipe elements).

Water used as service media is heated by live steam in a hot water preheater. A rotary pump feeds the hot water produced into the circulation system, which flows through the shell of the mash-heater. The heat transfers to the mash, which flows counter-currently through the inner tube of the heat exchanger module. The cooled water then flows back to the rotary recirculation pump. A safety valve and expansion tank is installed to prevent overpressure and volumetric expansion.

Type: hot water mash heater system

Number of sections: variable depending of output

Capacity: 10 to 120 t/h, 700–2’800 kW

Heating systems: hot water or low pressure steam (optional)

Temperature range: 5 to 85 °C

Automation: PLC based, visualisation with touchscreen

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain