Header Test

Header test paragraph library

Transport and conveying

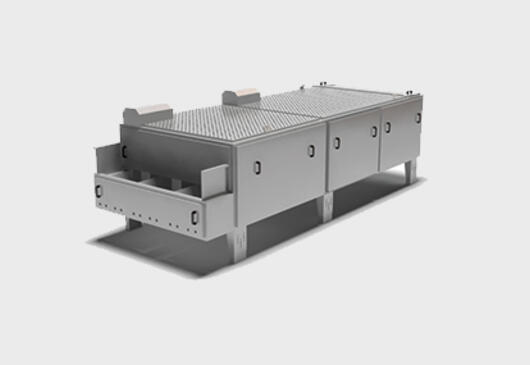

Reception Lines

- Flexible and storage capacity

- Fast unloading of the trucks

- Easy to clean / hygienic set-up

- Low maintenance cost

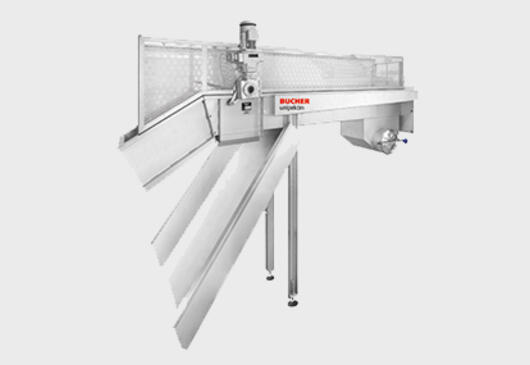

Dosing-Hasp

Dosing Hasp used for the flushing channel.

- Dosing and stopping devices for controlling the fruit flow

- Integrated water and dirt separation

- Optionally with stone trap

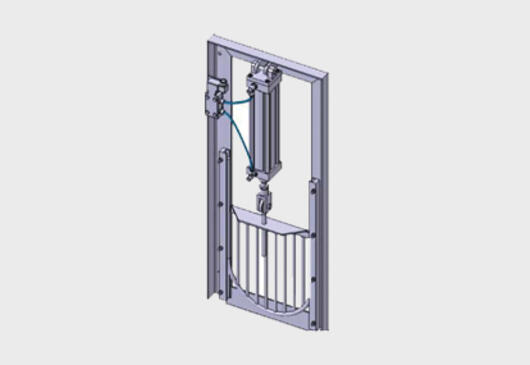

Dosing-Slide-Airmatic

Dosing Slide for water-tight closing of pome fruit silos and dosing into the flushing channel.

- Flooding of the silos enables unloading via truck

- Water-tight Airmatic seal

- Steady dosing of pome fruit into the flushing channel

Elevator

Vertical screw elevator for transporting pome fruit.

- High throughput with a small footprint

- High reliability with low maintenance

- Efficient separation of water and dirt

- Fresh water cleaning if needed

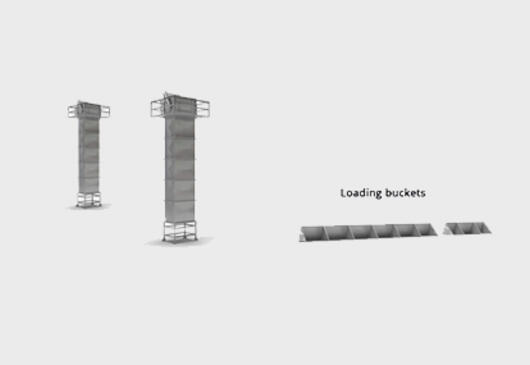

Vertical Bucket Elevator

High lifting capacity between high slopes using a small space.

Find out more

Roller Table

Roller table for sorting and cleaning of pome fruit

- Full inspection of fruit surface through rotating, gripped rollers

- Automatic dirt removal via rinseable tray underneath the belt

- Integrated cleaning nozzles

Citrus Sorting Table

Manual selection and rejection of citrus fruits of insufficient quality for processing.

Find out more

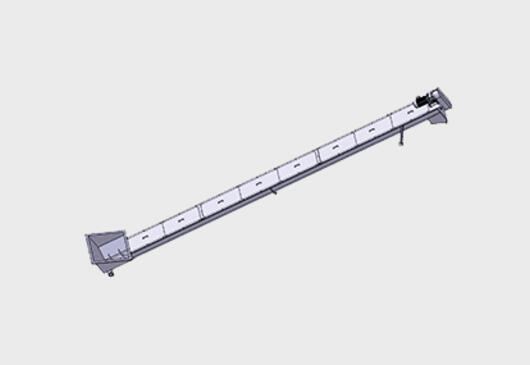

Dewatering Screw Conveyor

Dewatering screw conveyor for screenings.

- Screw conveyor with an integrated dewatering zone

- Transport and dewatering of screenings from the flushing water circuit

Transport Screw Conveyor

Transport screw conveyor for discharging and conveying of pomace.

- Variable length and inclination of the conveyor

- Robust design and execution

- Easy access

Dosing Slide

For isolate pome fruit silos and controlled dosing into the flushing channel.

- Variable opening and closing times

- Robust pneumatic drive

Citrus Brush Washer

Mechanical washing system with rotating brushes and water spray nozzles.

Find out more

Citrus Sizer

Inline calibration of citrus fruits using inclined rails with adjustable motorised rollers.

Find out moreSolids liquid separation

Exzelplus citrus juice extractor

Exzelplus extractor with 6 extraction heads for 20% more processing capacity

- Plus 20% capacity

- Oil recovery in just one stroke

- Separation of the juice from fruit peels and bitter substances

- Maximum juice yield

- Adaptable components

- Optional cleaning system

- Improved electrical cabinet with additional alarms

- New food grade solid plastic feeding tray

Bucher HPX presses

Universal hydraulic filter press for the extraction of juice from apples, pears, berries, stone fruits and vegetables.

- Highest juice yield with little suspended solid content

- Completely closed and secure hygienic design

- Integrated one to three step leaching system

- High reliability and low maintenance

- Self-optimising process control with data recording

- Proven unique design

Bucher HPS presses

Hydraulic filter press for dewatering of municipal and industrial sludge.

- High degree of dewatering

- Low disposal and drying costs

- Reliable process and control system

- Self-optimising process operation

- Continuous operation without supervision

- Minimal labour costs

- Minimal maintenance costs

Screw Finisher

High quality and performance solid - liquid separation system by rotating auger and perforated mesh, dragging and pressing the product throughout its length.

Find out more

Paddle Finisher

High quality and performance solid - liquid separation system by perforated mesh and helical paddles rotating at high speed, driving the product for sieving.

Find out more

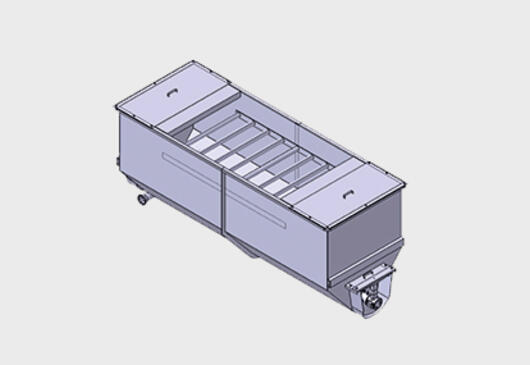

Collecting Screw Conveyor

Collecting Screw Conveyor for residue discharge from the Bucher HPX/HPS press.

- Hopper volume sufficient for residue of a press charge

- Fast discharge of the hopper

- Four sizes for 1–4 presses

Adsorption and Ion-Exchange systems

Adsorber

Adsorption systems for clear and cloudy fruit juices

- Ideal for haze-stabilisation, decolourisation and debittering to meet customer’s product specifications

- Enhanced product quality without the use of additives

- Minimal processing cost

- Fully automatic, PLC control and PC based operation systems

Ion-Exchanger

Ion exchange systems for treatment of fruit juices and syrups.

- Production of acid-reduced or deionised fruit juices and fruit sugar syrups according to specification

- Minimal processing cost

- Fully automatic, PLC control and PC based operator interface

Filtration

UltraStar XL

Crossflow ultrafiltration unit for the clarification of fruit juices, fruit wines, aqueous plant extracts, and fermentation broths.

- Maximum product yield and excellent juice quality

- Tubular membranes allow high solid concentrations

- Modular design, high performance on small footprint

- Reliable and fully automated system

- Integrated CIP system and tank management

Mona

Aseptic Filtration System

- Effective elimination of ACB bacteria

- Improvement of turbidity and microbiological quality of the concentrate

- Product safety during the process

- Monitoring and archiving of parameters

- Optimum use of filter plates

Cerinox MF

For wine, cider, fruit juice, vinegar and other food products.

- Standardised units

- Skid-mounted

- Ready to use

Synox 2.0 PF

New generation of candle filter for the most efficient and economical solution.

- Reduced pre- and post-run

- Reduced beer losses

- Reduced cleaning water consumption

FOM 110

For precoat filtration in various applications.

- Horizontal filter element

- Centrifugal discharge

- For syrup, beverages and food products

Microstar

Upgrade from a polysulfon filter to a modern ceramic filter.

- Easy, fast and economic

- Robust ceramic element

- Long service life

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain