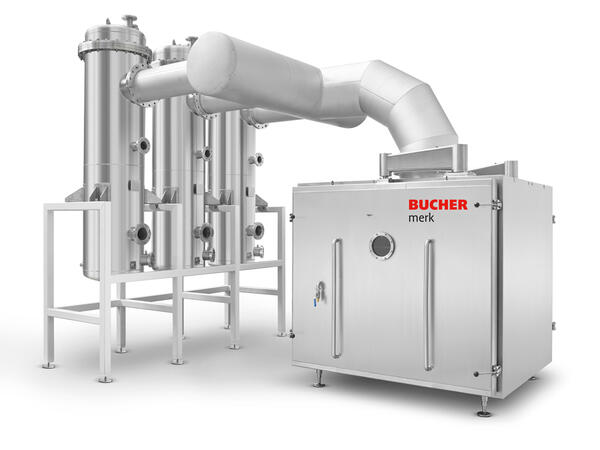

Zeolite Reactors

Zeolite reactors for the gentle vacuum drying or freeze-drying (lyophilisation) of products by using water adsorption.

- Best aroma retention

- Flexibility of production

- Selective process

- Batch or continuous process

Bucher Zeodration systems are designed for drying a wide range of herbal and plant extracts, fruits, vegetables, herbs, bacteria, and other products for the food and cosmetic industry.

Our Zeodration technology offers a drying solution for liquid or solid products down to a residual moisture content of less than 0.5%. This process is successfully used for temperature sensitive products and to achieve maximum product quality.

The Bucher Zeodration system uses Zeolite reactors to trap the water or solvent. Zeolite is crystallised clay with a pore diameter of 4 Angstroms (water molecules are 3 Angstroms). Its properties, combined with polarity factors, lead to a selective moisture trap that under operating pressure conditions, retains water only.

Because of a very low partial pressure at the water adsorption, a maximum reduction of lost volatile molecules through the vacuum system is achieved, maintaining most of the flavours in the product. While using Bucher Zeodration with vacuum dryers, a similar product-quality can be achieved as with freeze-drying systems. Due to an integrated and cyclic regeneration of the Zeolite, the full adsorption capacity is maintained. The application of zeolite reactors offers interesting features as it permits a drying operation in the pressure range of 0.5–30m bar.

Zeodration can be combined with a Bucher vacuum cabinet dryer for batch production or a Bucher vacuum belt dryer for continuous production.

Adsorption capacity: 1 to 1000 kg/h water

Batch drier sizes: 0.2–88m2 heating surface

Belt dryer sizes: 0.6–325m2

El. installed power: 15 to 80 kW

Heating energy for regeneration: up to 900 kW

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain