Reception Line Pomegranate

Our reception lines are proven worldwide for reception, cleaning and conveying of fruits for the juice production.

Equipment and machinery for the reception, cleaning and peeling of pomegranate

- From fruit reception to mash tank

- Large reception and inspection belt

- Optional washing of fruit with water circulation

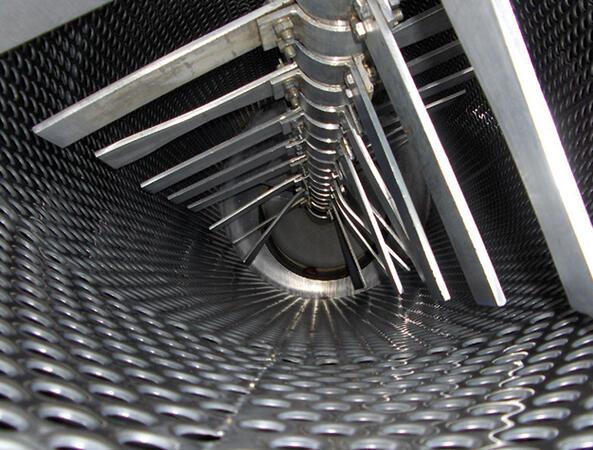

- Gentle disintegration of fruit

- Efficient separation of skin and grains

Delta reception lines for pomegranate typically consist of reception belts for tipping and inspecting the fruit, washing section with optional water circulation, inclined elevator and peel separation units. All equipment has a long service life combined with low maintenance cost and high reliability. One of the main focuses of the machines is the gentle handling of the fruit to achieve maximum product quality with minimum juice bitterness.

The pomegranates typically are delivered on trucks in boxes or nets. The fruit will be tipped onto the reception belt with side guides and sorting section. On the inclined elevator fruit washing can be done and the water can optionally be cleaned via a water sieve and reused. For final rinsing fresh water is used. The rotary fruit breaking and peeling unit is optimised for efficient peel separation and highest juice quality. For small and hard fruit an optional precrusher is available.

Reception lines are available with throughputs of approx. 6 t/h up to 30 t/h. All parts in contact with the product are made of stainless steel 1.4301 (AISI 304) or other food grade material.

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain