MiniStar

Compact cross-flow ultrafiltration unit for the clarification of fruit juices and wines, aqueous plant extracts, and fermentation broths

The MiniStar comes as a preassembled and tested unit on a compact frame with all the required periphery tanks «on board». Integrated into an existing processing line and the operation of the unit are simple. The MiniStar is a semicontinuous cross-flow filtration plant.

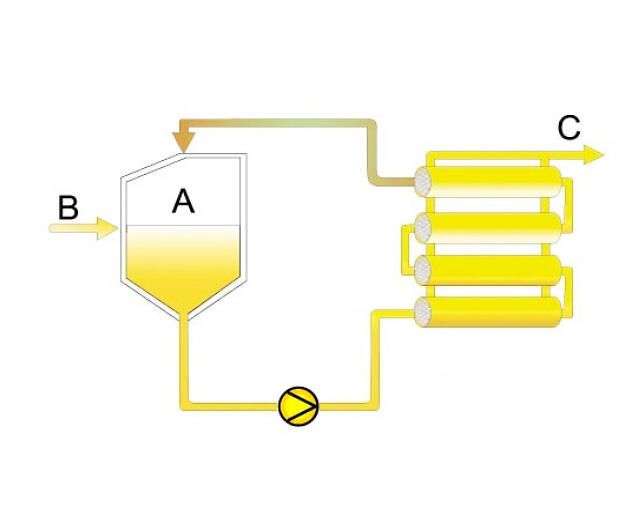

The product, which shall be clarified (B), is circulated via a circulation tank (A) through the inside of the ½ inch membrane tubes. A portion of the liquid phase thereby permeates through the thin membrane layer and leaves the system as permeate (C). Fresh product (B) is continuously added into the circulation tank (A).

As soon as the maximum concentration of suspended solids has been achieved, the retentate is extracted with the water (optional) to maximise the yield. Due to its modular design the MiniStar can be equipped with a number of different of stainless steel or organic (PVDF) membranes.

The Bucher Unipektin MiniStar has been designed for small and medium sized producers of fruit juices, fruit wines and extracts from plant material. Due to its large diameter tubular membranes it is predestined for the clarification of aqueous liquids with medium to high suspended solids content. Different membranes cut off and materials enable an adaptation to various applications.

Membrane modules: KMS Super-Cor®, Scepter®

Membrane types: UF (HFM 180), MF (HFM 513 or stainless steel)

Membrane area: 14–88m2

Temperature range: 10–55 °C (stainless steel up to 95 °C)

pH-range: 2.0–10.5 (stainless steel up to pH 14.0)

Connected load: 7.5–18.5 kW

Dimensions Units > 44m2 : 4’270 x 2’340 x 2’415 (W x D x H in mm) Units < 35m2 : 3’380 x 1’555 x 2’167 (W x D x H in mm)

Scope of supply: circulation unit with control cabinet, filter rack, circulation tank, permeate tank and water tank assembled on frame.

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain