HP Presses for rental

We offer the following hydraulic presses for solid-liquid separation of fruits.

HP 14

The HP 14 compact hydraulic laboratory press is especially well suited for low-turbidity separation of liquids and solids in small quantities and for tests of all types at laboratory scale.

The range of applications are for exemple pomaceous fruits, stone fruits, berries, vegetables, exotic fruits, herbs, plants and other raw materials.

Press Volume: 14 l

Availible for inhouse and on site trials.

HPL 207

The HPL 207 is a fully automated hydraulic press designed for Trials and and small production. Due to the unique technology in combination with the automatic process sequence, high throughput and maximum yields are achieved. Hygienic juice extraction with low solids is accomplished due to closed pressing system with internal drainage filter elements.

The HPL 207 press is designed as a rotating hydraulic piston-cylinder system. Flexible drainage elements for solid-liquid separation, filtrate discharge and loosening of the pomace are installed between the pressure and the filtrate plates. After filling the press with product through the central inlet, a sequence of pressing cycles is executed until the desired pressing result is achieved. By feeding water into the press (Leaching), mixing it with the pomace and pressing again the yield can be further increased. The range of applications are for exemple pomaceous fruits, stone fruits, berries, vegetables, exotic fruits, herbs, plants and other raw materials.

Press Volume: 200L

Availible for inhouse and on site trials.

HP 1600

The HP 1600 is a hydraulic press designed for for pilot trials and small industrial scale production in the area of solid-liquid separation applications in the food industry. Due to the unique technology in combination with the automatic process sequence, high throughput and maximum yields are achieved. Hygienic juice extraction with low solids is accomplished due to closed pressing system with internal drainage filter elements.

The HP 1600 press is designed as a rotating hydraulic piston-cylinder system. Flexible drainage elements for solid-liquid separation, filtrate discharge and loosening of the pomace are installed between the pressure and the filtrate plates. After filling the press with product through the central inlet, a sequence of pressing cycles is executed until the desired pressing result is achieved. By feeding water into the press (Leaching), mixing it with the pomace and pressing again the yield can be further increased. The range of applications are for exemple pomaceous fruits, stone fruits, berries, vegetables, exotic fruits, herbs, plants and other raw materials.

Press Volume: 1600L

Only availible for on site trials.

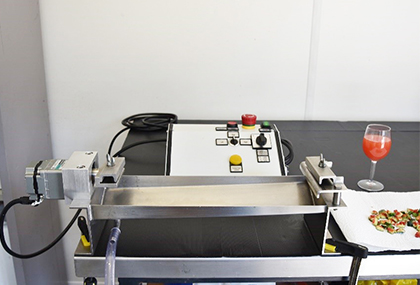

Bucher Twisting Test (BTT)

The Bucher Twisting Test Equipment (BTT) is used to determine the dewaterability of all kinds of products. The results of a trial with the BTT give insight about the achievable dryness in the filter cake, when pressed with a hydraulic Bucher press.

Availible for inhouse and on site trials.

Switzerland

Switzerland  Poland

Poland

Czech Republic

Czech Republic  Germany

Germany

Spain

Spain