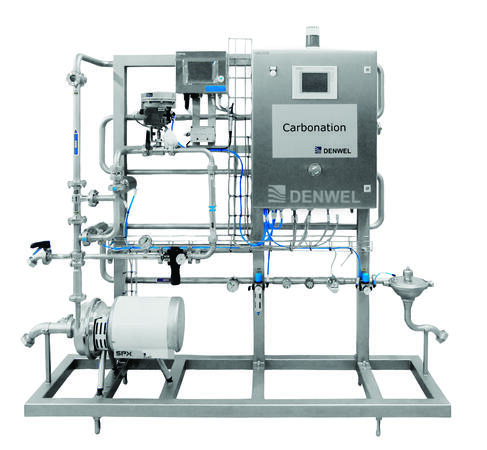

Inline Karbonisierung

Automatische Anlage

Automatische Anlage

Für die effiziente Karbonisierung von Getränken

- Mikroblasen

- sofortige CO2-Sättigung

- Präzise CO2-Injektion

- CO2-Analysator geregelt

CO2 ist ein wesentlicher Bestandteil von kohlensäurehaltigen Getränken. Es verstärkt den Geschmack und den Körper des Produkts, und der Effekt des Sprudelns prägt den erfrischenden Geschmack des Getränks. Der CO2-Gehalt beeinflusst auch die Schaumstruktur und die Stabilität des Bieres. Daher ist eine konstante und genaue CO2-Konzentration einer der wichtigsten Qualitätsfaktoren bei der Produktion von Bier und alkoholfreien Getränken. Bucher Denwel bietet eine vollautomatische Lösung für die kontinuierliche Karbonisierung an, die für eine schnelle und präzise Injektion und Auflösung von CO2 ausgelegt ist.

CO2 wird durch einen Bucher Denwel Injektor in Form von Mikroblasen in das Getränk injiziert. Das CO2 wird mit minimalem Druckabfall, ohne Gasverlust sofort und effizient gelöst. Es werden keine statischen Mischer oder Sinterkerzen benötigt. Das System wird über eine SPS gesteuert und verfügt über automatische Modi für die kontinuierliche Karbonisierung sowie die CIP-Reinigung. Der selektive Inline-CO2-Analysator überwacht kontinuierlich die CO2-Konzentration.

Das Ausgangssignal wird von der SPS verarbeitet, um die CO2-Dosierung zu steuern. Ein hochpräzises Regelventil passt die CO2-Injektion genau an, um eine Über- oder Unterkarbonisierung zu vermeiden. Das Gegendruckventil hält den Druck im System trotz etwaiger Änderungen im Durchfluss konstant. Ein konstanter Systemdruck gewährleistet eine schnelle und genaue Steuerung der CO2-Dosierung.

Karbonisierung: bis zu 6 g/l, 3 V/V (abhängig von D & T)

Druck: Betriebsdruck 2 bis 5 bar, 30 bis 72 psig

Temperatur: Betriebstemperatur 0 bis 5 °C, 32 bis 40 °F

CIP: 2 bis 5 bar, 30 bis 72 psig; max. 90 °C, 200 °F

Anschluss: Tri-Clamp; andere Anschlüsse auf Anfrage

Abmessungen: ab Höhe 1,9m, 6,2'; Breite 2,0m, 6,5'; Tiefe 0,6m, 2'

Gewicht: ab 200kg, 440 lb

Material: Rostfreier Stahl 304, EPDM, PSU, PP

Schweiz

Schweiz  Polen

Polen

Tschechien

Tschechien  Deutschland

Deutschland

Spanien

Spanien